Winter HVAC Prep: 5 Steps How to Slash Energy Costs and Avoid Downtime (Easy Guide for Commercial Properties)

Winter is coming, and your commercial HVAC system is about to face its biggest test of the year. As temperatures drop across South Jersey, heating costs can skyrocket while the risk of unexpected system failures increases dramatically. The good news? A few strategic preparation steps taken now can save you thousands in energy costs and prevent costly emergency repairs during peak heating season.

At South Jersey Heating and Cooling, we've seen firsthand how proper winter preparation makes the difference between smooth sailing and emergency service calls at 2 AM. After years of helping commercial property owners optimize their HVAC systems, we've identified five critical steps that deliver the biggest impact on both energy efficiency and system reliability.

Whether you manage an office building, retail space, or industrial facility, these proven strategies will help you slash heating costs while keeping your tenants comfortable and your business running smoothly all winter long.

Step 1: Replace Air Filters and Perform Essential Air System Maintenance

Your air filters are the unsung heroes of energy efficiency, yet they're often the most neglected component of commercial HVAC systems. Dirty filters are energy vampires: they force your system to work significantly harder to push air through clogged media, driving up energy consumption and creating unnecessary wear on your equipment.

Start by replacing all heating equipment filters immediately. For most commercial applications, filters should be changed every 1-3 months, but you'll want to inspect them more frequently during heavy-use periods or if your building generates significant dust or contaminants.

Clean filters improve airflow efficiency by up to 15%, which directly translates to lower energy bills and reduced strain on system components. When your HVAC system can breathe freely, it reaches temperature setpoints faster and cycles less frequently.

Don't stop at filter replacement. Schedule routine lubrication of all motors and bearings throughout your system. This simple maintenance step prevents sudden equipment failures that typically occur during the highest-demand winter months when your system is working hardest. A seized motor or failed bearing doesn't just mean an uncomfortable building: it means expensive emergency repairs and potential business disruption.

Pro tip: Keep a log of filter change dates and condition assessments. This data helps you optimize replacement schedules and identify areas of your building that may need additional air filtration or source control.

Step 2: Calibrate Thermostats and Optimize Building Controls

Your thermostat settings represent one of the fastest ways to reduce energy costs without sacrificing comfort. Most commercial buildings waste significant energy by heating unoccupied spaces to full comfort temperatures during nights, weekends, and holidays.

Implement setback schedules that reduce heating temperatures by 5-10 degrees during unoccupied hours. This simple adjustment can cut your heating costs by 10-20% without any capital investment. The key is programming these setbacks to align with your actual occupancy patterns, not just standard business hours.

If you're still using basic thermostats, consider upgrading to programmable or smart controls that can automatically adjust temperatures based on occupancy schedules. Modern building automation systems can even learn your building's thermal characteristics and begin warming up spaces at precisely the right time to reach comfortable temperatures when employees arrive.

For buildings with economizers and damper systems, verify that all components are functioning correctly. Economizers can provide free cooling during mild winter days, reducing the load on your heating system and lowering energy consumption.

Review and optimize all control sequences to ensure heating equipment isn't fighting cooling equipment. We've found many commercial buildings where simultaneous heating and cooling occurs due to poorly configured controls: a costly mistake that drives up energy bills unnecessarily.

Step 3: Seal the Building Envelope and Stop Energy Leaks

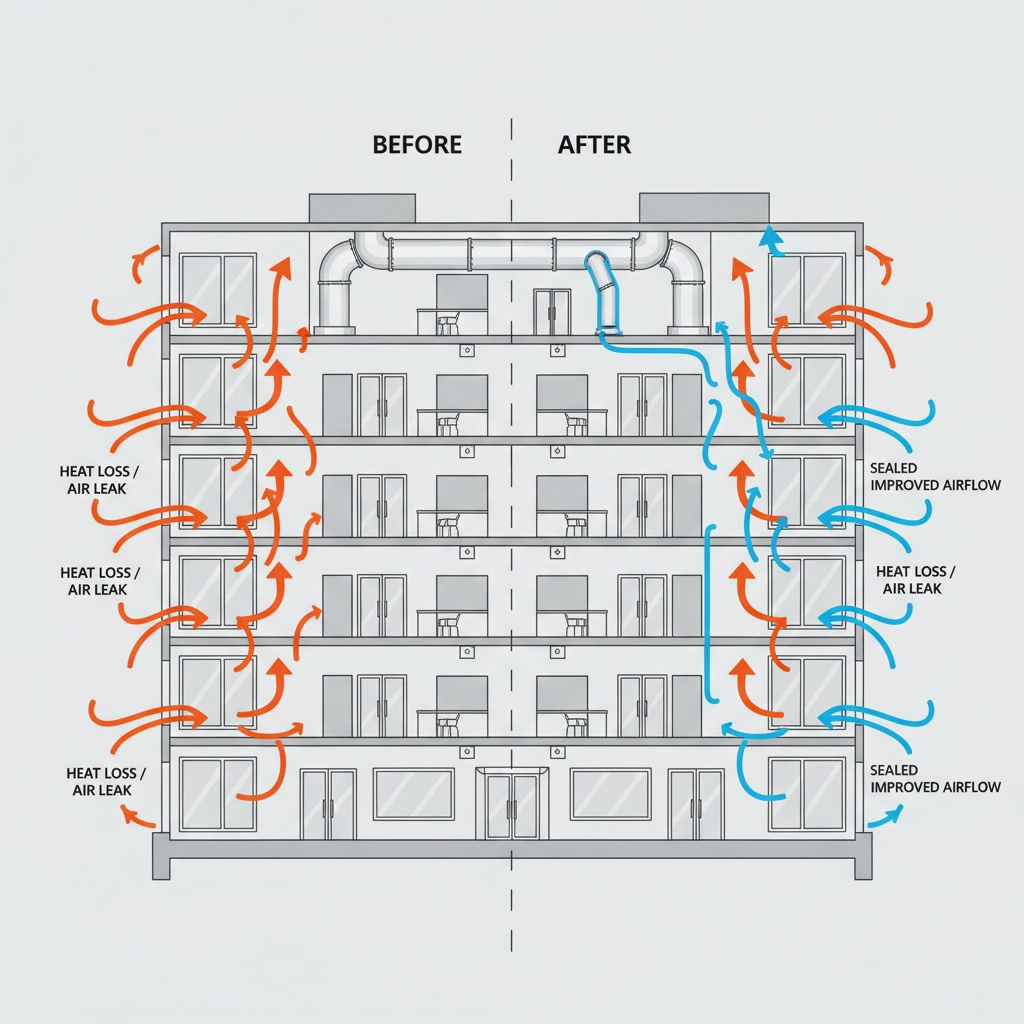

Air leaks are silent budget killers. Every gap, crack, and poorly sealed connection allows expensive heated air to escape while letting cold air infiltrate your building. This forces your HVAC system to work continuously to maintain temperature setpoints.

Conduct a thorough inspection of your ductwork, paying special attention to joints, connections, and areas where ducts pass through walls or floors. Seal any leaks using appropriate materials: mastic sealant for smaller gaps and metal tape or clamps for larger connections.

Walk through your entire facility to identify air leaks around windows, doors, loading docks, and other exterior openings. Pay particular attention to:

- Weather stripping around entry doors and windows

- Loading dock seals and levelers

- Gaps around utility penetrations

- Vestibule door operations

- Roll-up door seals

Don't overlook your mechanical rooms and equipment areas. Insulate all exposed hot water and heating pipes, especially in unheated spaces like parking garages, mechanical rooms, and perimeter areas. Proper pipe insulation prevents heat loss and protects against freeze damage that could shut down your entire system.

For buildings with older insulation, consider having an energy audit performed to identify areas where improved insulation could deliver significant energy savings. Even small improvements in building envelope performance compound over an entire heating season.

Step 4: Complete Comprehensive Preventive Maintenance

Preventive maintenance is your insurance policy against winter breakdowns. Small issues that seem manageable during mild weather often become major failures when your system is operating at peak capacity during cold snaps.

Schedule professional maintenance that includes thorough inspection and cleaning of critical heating components:

Heat exchangers and burners require detailed inspection for cracks, corrosion, or debris buildup that could reduce efficiency or create safety hazards. Even minor damage can significantly impact heating performance and energy consumption.

Coil cleaning is essential for optimal heat transfer. Dirty coils force your system to run longer cycles to reach setpoints, wasting energy and increasing wear. Clean coils also improve indoor air quality by preventing the circulation of accumulated contaminants.

Safety system testing ensures all high-limit controls, flame sensors, and combustion safety devices function correctly. This isn't just about preventing breakdowns: it's about protecting your building occupants and avoiding liability issues.

Gas pressure and combustion analysis verifies that your heating equipment is operating efficiently and safely. Improper combustion not only wastes fuel but can create dangerous conditions.

Electrical connection inspection prevents failures that often occur when systems are under heavy load during cold weather. Loose connections create heat, reduce efficiency, and can lead to equipment damage or fire hazards.

At South Jersey Heating and Cooling, we recommend establishing a relationship with a qualified commercial HVAC contractor who can provide regular maintenance and emergency service. Having 24-hour emergency coverage gives you peace of mind and ensures rapid response when issues arise.

Step 5: Implement Freeze Protection and Emergency Preparedness

Freeze protection isn't just about preventing pipe damage: it's about ensuring your entire HVAC system continues operating reliably throughout winter's most challenging conditions.

Set unoccupied heating temperatures high enough to protect vulnerable piping and equipment in perimeter zones and mechanical rooms. Typically, this means maintaining temperatures at least 10-15 degrees above freezing in all areas containing water lines or HVAC equipment.

Configure your building automation system to maintain minimum air and water circulation during unoccupied periods. Keep supply fans running at low speed and ensure circulation pumps cycle regularly to prevent stagnation and freeze-ups in vulnerable areas.

Implement temperature monitoring and alarm systems for critical areas like mechanical rooms, perimeter zones, and any spaces containing water lines. Early warning of temperature drops allows you to take corrective action before problems occur.

Develop an emergency response plan that includes contact information for your HVAC service provider, utility companies, and key building personnel. Ensure someone is always available to respond to after-hours alarms and emergencies.

Stock essential spare parts like filters, belts, and basic components that could fail during peak heating season. Having these items on hand can mean the difference between a quick repair and extended downtime waiting for parts delivery.

Take Action Now for Winter Success

These five steps represent proven strategies that commercial property owners across South Jersey use to reduce energy costs and prevent winter HVAC emergencies. The investment in proper preparation always pays dividends through lower utility bills, reduced repair costs, and uninterrupted business operations.

Don't wait until the first major cold snap to discover problems with your heating system. Start implementing these steps today, beginning with the simple tasks like filter replacement and thermostat programming, then scheduling professional maintenance for more complex components.

If you need assistance with any of these winter preparation steps, South Jersey Heating and Cooling is here to help. Our experienced technicians understand the unique challenges of commercial HVAC systems and can develop a customized maintenance plan that fits your building's needs and budget.

Contact us today at 609-488-2253 to schedule your pre-winter maintenance or to discuss energy-saving upgrades for your commercial property. Let us help you slash your energy costs and avoid winter downtime this season.