Is Your Commercial HVAC System Ready for 2025? Here Are 10 Things You Should Know

South Jersey Heating and Cooling

info@sjhcservice.com

609-488-2253

As we enter 2025, commercial property owners across South Jersey face unprecedented changes in HVAC regulations and technology. The decisions you make this year will impact your building's comfort, energy costs, and compliance for years to come. At South Jersey Heating and Cooling, we've been helping businesses navigate these transitions, and we want to share the ten most critical things you need to know right now.

1. The R-410A Refrigerant Phase-Out is Here

The biggest change affecting commercial HVAC systems started January 1, 2025. All new residential and light commercial air conditioners and heat pumps must now use alternative refrigerants with lower global warming potential. This means R-410A refrigerant: the standard for the past two decades: is officially being phased out for new equipment.

The Environmental Protection Agency has set a 750 global warming potential (GWP) limit for air conditioning systems. R-410A exceeds this limit, making it obsolete for new installations. This regulatory shift, driven by the American Innovation and Manufacturing Act of 2020, fundamentally changes how HVAC equipment is manufactured and installed.

What does this mean for your business? If you're planning any HVAC upgrades or expansions this year, you'll need to work with contractors who understand the new refrigerant requirements and can recommend compliant alternatives.

2. You Have a Grace Period: But Not For Long

Here's some good news: equipment manufactured before 2025 can still be installed until January 1, 2026. This one-year grace period provides crucial flexibility for businesses with planned installations or ongoing projects.

However, this window is closing fast. Smart facility managers are using this time to:

- Complete comprehensive system evaluations

- Plan major installations or replacements

- Secure equipment while it's still available

- Work with qualified contractors to develop transition strategies

Don't wait until the last minute. The grace period gives you time to make informed decisions rather than rushed ones.

3. System Age Matters More Than Ever

If your commercial HVAC system is over 10 years old, 2025 is the perfect time for a comprehensive evaluation. Aging systems typically show decreased performance, higher energy consumption, and increased maintenance costs: problems that become more expensive as new efficiency standards take effect.

Key indicators that suggest your system needs attention include:

- Frequent breakdowns and increasing downtime

- Rising energy bills compared to previous periods

- Inconsistent temperature control throughout your building

- Diminishing indoor air quality with increased dust, odors, or humidity issues

- Repair costs approaching 50% of a new system's price

Modern commercial HVAC technologies offer significantly improved energy efficiency, with potential annual savings ranging from 20% to 40% compared to older systems.

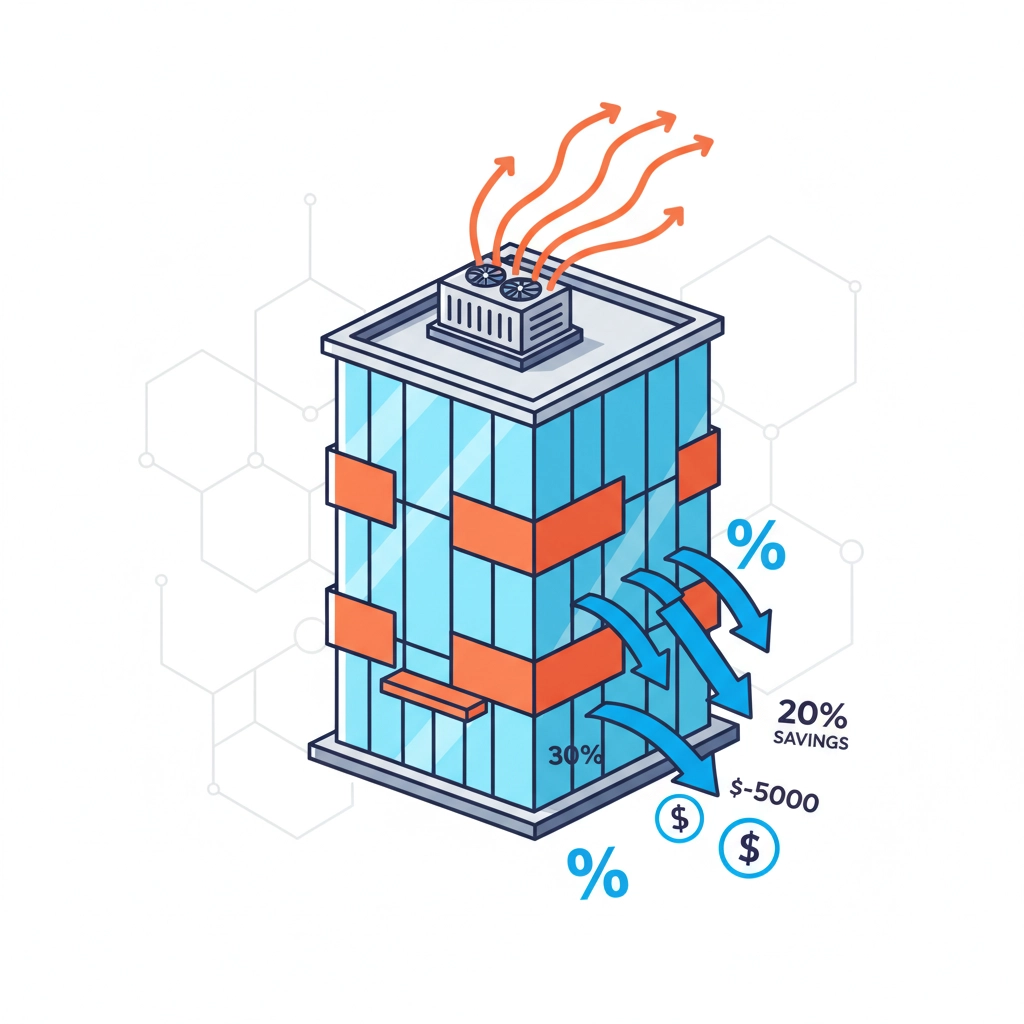

4. Energy Efficiency Can Transform Your Bottom Line

HVAC systems account for 40-50% of a commercial building's total energy expenditure. That means every efficiency improvement directly impacts your operating costs. Advanced heat pump technologies, AI-driven climate control systems, and improved refrigerant compositions are reshaping how businesses think about energy consumption.

High-performance HVAC equipment can potentially reduce annual energy costs by 30%, with payback periods typically ranging between three to five years. When you factor in rising energy prices and new efficiency standards, upgrading becomes not just an environmental choice but a financial necessity.

The key is working with experienced professionals who can calculate your specific savings potential based on your building's unique characteristics and usage patterns.

5. Federal Tax Credits Are Available Now

The federal government is supporting businesses making efficiency upgrades. The Inflation Reduction Act provides 25C tax credits up to $2,000 for qualifying equipment. These credits are based on performance requirements established by the Consortium for Energy Efficiency and became effective January 1, 2025.

To qualify, your new equipment must meet specific energy efficiency standards. This is where working with knowledgeable contractors becomes essential: they can ensure your investment qualifies for maximum tax benefits while delivering optimal performance.

6. VRF Technology is Dominating Commercial Growth

Variable Refrigerant Flow (VRF) systems represent one of the most significant technological advancements in commercial HVAC. These systems allow precise temperature management across different building zones, delivering substantial energy savings and improved comfort.

VRF technology offers several advantages:

- Individual zone control for different areas of your building

- Simultaneous heating and cooling capabilities

- Reduced energy consumption through intelligent load management

- Quiet operation suitable for office environments

- Scalability for buildings of various sizes

VRF systems may also receive extended timelines for refrigerant compliance, giving you more flexibility in planning upgrades.

7. Code Compliance Requirements Have Evolved

Federal and state building energy efficiency standards have updated their requirements for 2025. Federal buyers must ensure that commercial central air conditioners and air source heat pumps are installed in accordance with HVAC Quality Installation (QI) standards.

California has also updated its building energy efficiency standards, and other states are following suit. What this means for your business:

- Professional installation is more critical than ever

- Documentation requirements have increased

- System commissioning standards are more stringent

- Regular maintenance protocols may be mandated

Working with certified contractors who understand current codes ensures your system meets all compliance requirements from day one.

8. New Refrigerants Offer Different Performance Characteristics

New HVAC systems will use R-454B or R-32 refrigerants to replace R-410A. While your existing systems aren't affected, new equipment will have different performance characteristics, costs, and maintenance requirements.

These new refrigerants:

- Have lower global warming potential

- May require different handling procedures

- Could affect system efficiency ratings

- Might influence equipment pricing

- May need specialized technician training

At South Jersey Heating and Cooling, our technicians are already trained on these new refrigerants, ensuring smooth transitions for our commercial clients.

9. Smart Controls and Monitoring Are Essential

Modern commercial HVAC systems feature IoT-enabled environmental controls, predictive maintenance technologies, air quality monitoring systems, and remote management capabilities. These aren't luxury features: they're becoming necessities for efficient operation and compliance.

When selecting new equipment, evaluate systems based on:

- Seasonal Energy Efficiency Ratio (SEER) ratings

- Energy Star certification

- Smart control system capabilities

- Integration with building management systems

- Data analytics and reporting features

These technologies don't just improve comfort: they provide the documentation and control capabilities that modern building codes increasingly require.

10. Professional Consultation is More Important Than Ever

The HVAC industry is expected to invest over $10 billion in repair and maintenance services in 2025, indicating the scale of changes affecting businesses nationwide. With new refrigerants, updated codes, evolving technologies, and federal incentives all converging, professional guidance isn't optional: it's essential.

Working with experienced contractors helps you:

- Navigate regulatory changes confidently

- Maximize available incentives and rebates

- Select equipment that meets your specific needs

- Ensure proper installation and compliance

- Plan maintenance strategies that protect your investment

Each commercial property has unique requirements based on square footage, ceiling height, thermal insulation, occupancy levels, and operational zones. Different property types: office buildings, warehouses, retail spaces, healthcare facilities, and manufacturing environments: need distinctly different HVAC solutions.

Take Action Now

The convergence of regulatory changes, technological advances, and financial incentives makes 2025 a pivotal year for commercial HVAC decisions. The grace period for equipment installation won't last forever, and early action gives you more options and better outcomes.

South Jersey Heating and Cooling has been helping businesses navigate these transitions successfully. Our certified technicians understand the new regulations, are trained on emerging technologies, and can help you develop a strategy that meets your immediate needs while positioning your business for long-term success.

Don't let regulatory changes catch you off guard. Contact South Jersey Heating and Cooling at 609-488-2253 to schedule a comprehensive system evaluation. We'll help you understand your options, maximize available incentives, and ensure your commercial HVAC system is ready for 2025 and beyond.

Your building's comfort, efficiency, and compliance depend on the decisions you make today. Let our expertise guide you through these important choices.

South Jersey Heating and Cooling

info@sjhcservice.com

609-488-2253